Tuberculosis (TB) control and prevention activities rely on a well-functioning laboratory system. That is why the laboratory is the backbone for the programmatic and clinical management of TB. Despite this, TB laboratory services are facing many challenges that affect the quality and quantity of services at various levels of the laboratory network in Ethiopia. One of these challenges is laboratory supply chain management. TB laboratory services use distinct types of supplies with unique features and as a result, the supply chain management is expected to be responsive to these characteristics of products. One of the key functions of TB supply chain management is the quantification of products.

“Due to the lack of any standardized tool and the complexity of lab commodities, TB lab supplies quantification was very difficult. We were forced to estimate the items needed by each health facility.” ” remembered Misikir Tesfaye from the Ethiopian Pharmaceuticals Supply Services (EPSS)

There was no standardized quantification tool to quantify TB laboratory supplies in Ethiopia for many years. As a result, there were no exhaustive product lists available and for those that were available, they were not standardized according to the requirement of each lab service provided. This resulted in the mismanagement of the supplies as some facilities were overstocked while some were facing stockout.

“This has affected the process of forecasting and distribution of TB lab supplies. The lack of a standardized quantification tool has also resulted in delaying and finalizing the whole quantification process. The quantification exercise was being done manually and it was a very tedious process as the number of products is too many (>200) and many of them were used in different TB lab services at the same time.” said Misikir.

As a result, the finalization of the whole quantification process, including the medicines, and report write-up was delayed by weeks (months sometime) due to the delay in the lab quantification. The manual quantification process was error-prone, and it was also the main reason for the poor quality of data generated with low or over-quantified products which can ultimately end up in stockout or loss of products through expiry.

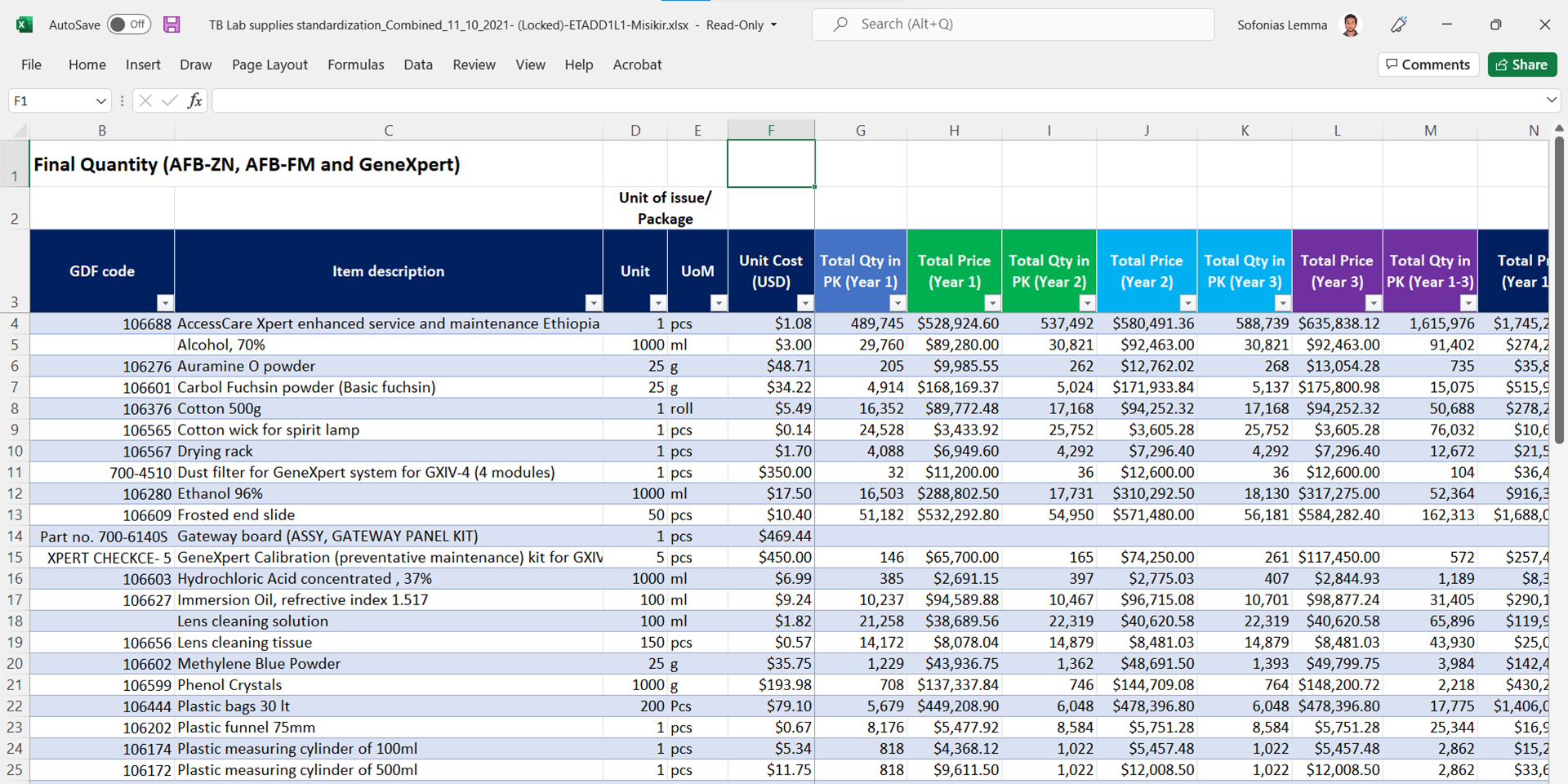

Understanding the situation, the USAID Global Health Supply Chain Program-Procurement and Supply Management (GHSC-PSM) project in collaboration with Ethiopian Public Health Institute (EPHI) supported the development of a standard Excel-based quantification tool for all TB laboratory products. The activity began by organizing a series of workshops to standardize the list of products by category of tests and determine the number of tests per parameter. After standardization, an Excel-based tool was developed.

The quantification tool has enabled TB supplies to have a comprehensive list of products in each category of test and avoided missing supplies during quantification. The tool has also simplified the overall process of quantification by improving the quality of data. In addition to this, it has shortened the lengthy process of quantification and writing up which was the main challenge during previous years. The tool was tested and used in the FY21 quantification exercise, and it enabled the team to finalize the quantification and write-up of TB lab supplies within five days together with other TB medicines for timely placement of orders.

Even though it is difficult to measure the exact quantification error before and after the development of the tool due to the lack of actual consumption data, the tool averted errors that were witnessed during order processes. Currently, the data generated by the tool is being used for supply planning and ordering TB laboratory supplies.