- Different and proprietary item identifiers assigned at various points of the supply chain

- Inconsistent labelling of products across suppliers

- Inability to automatically capture identification data

- Incomplete or inaccurate product master data that define key attributes of the net, such as dimensions, insecticide type, and manufacturer

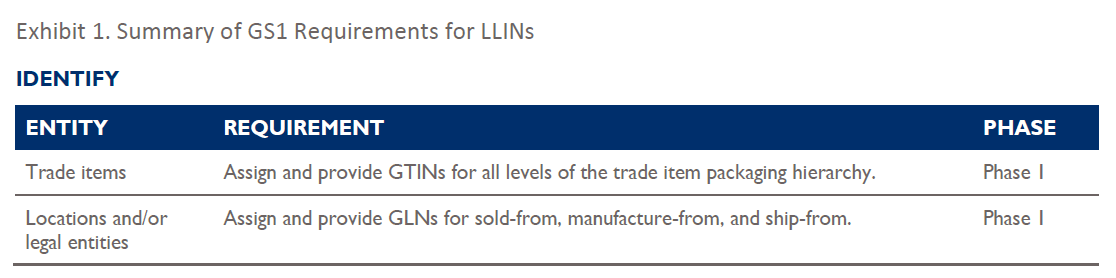

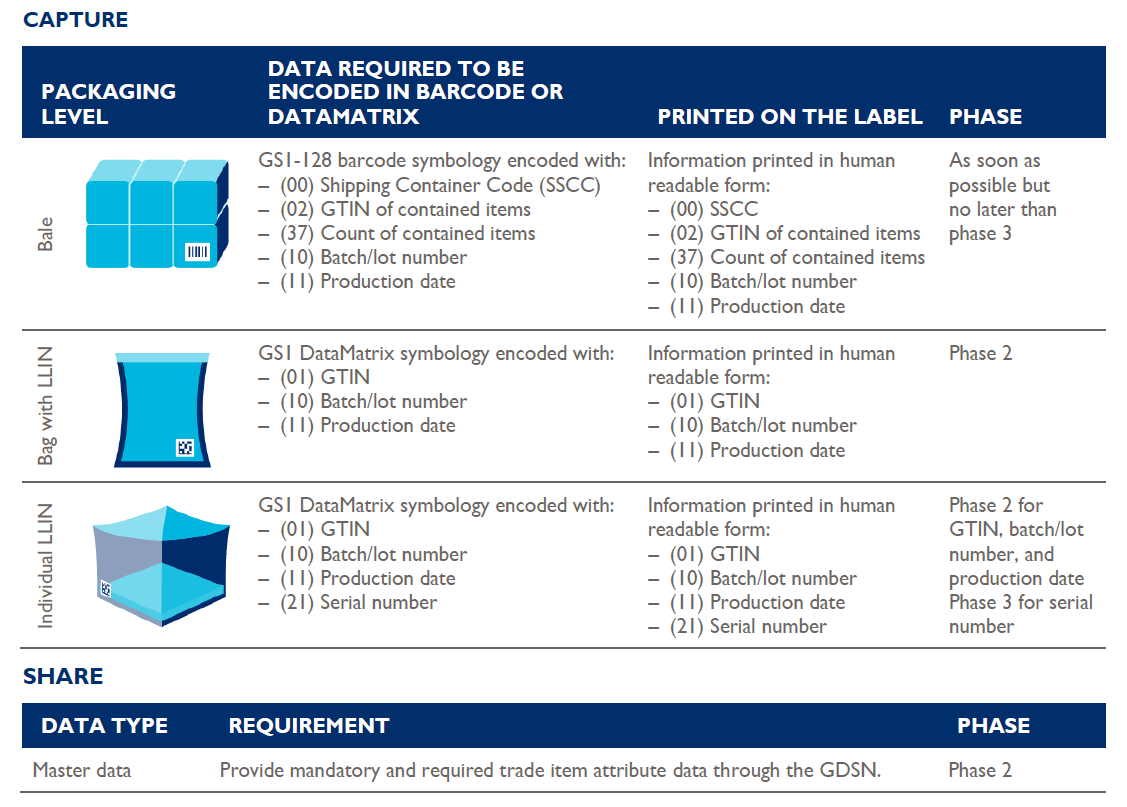

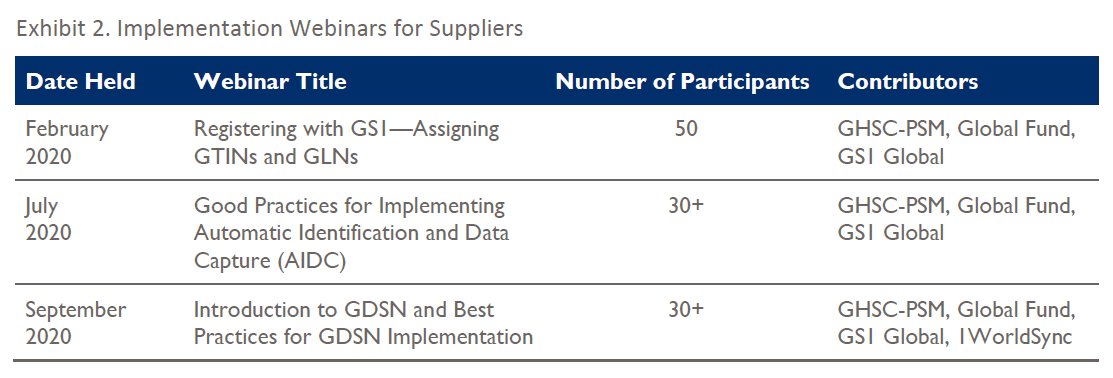

These challenges create a high-maintenance, error-prone environment that increases complexity, inaccuracy, and cost—and can be prohibitive to tracking where a net is going and tracing backwards to know where it has come from. Trade partners can uniformly identify nets with the same level of precision and consistent identifiers by adopting a common business language—a global standard—that can be used by all trading partners, from manufacturer to dispenser, to identify, capture, and share information about the LLIN and its movement in the supply chain. Using such standards enables interoperability across supply chain information systems, enhancing the quantity and quality of data available to support operational processes.