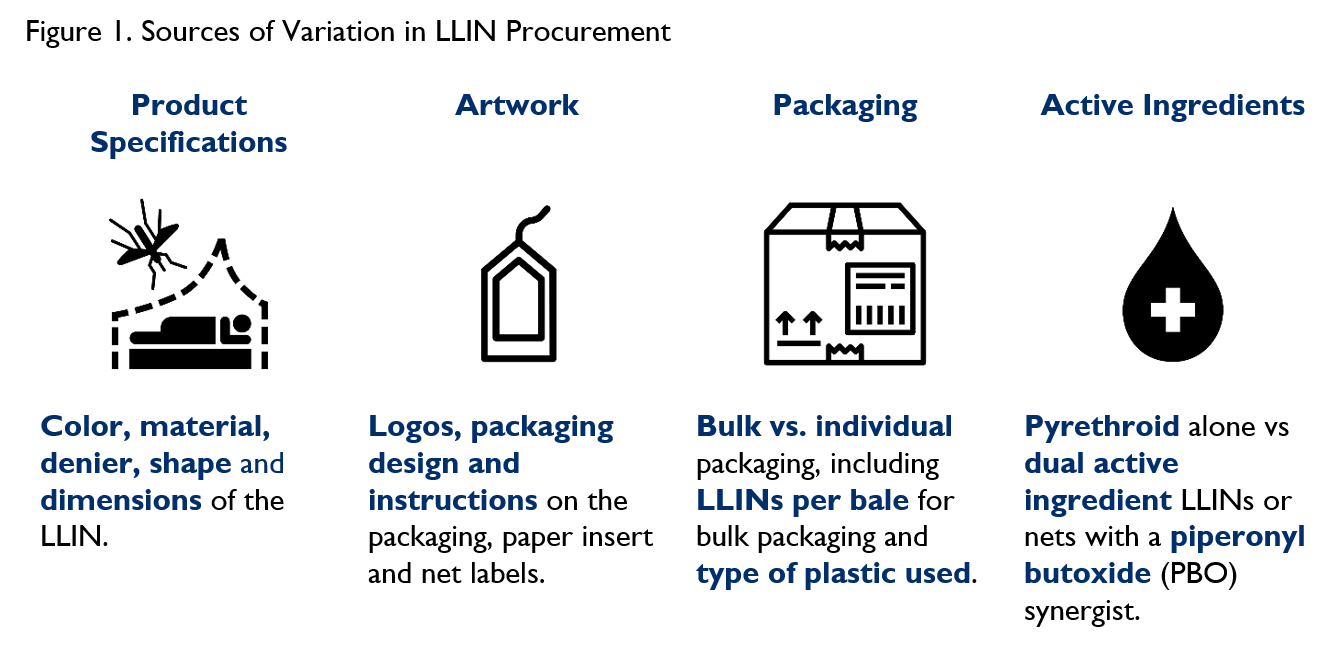

LLINs are produced based on various product specifications, including material, dimensions, active ingredients, color, shape, artwork, and packaging (see Figure 1). In 2017, GHSC-PSM initiated a broad study, which found that PMI had historically purchased nets with many different specification variations, even before countries added customization like logos and instructions. With those made-to-order customizations, there were more than 35 different final LLIN product variations across more than 20 countries.

The project’s 2017 study examined all of these net variations to weigh the benefits of streamlining LLIN production into fewer options that would still appeal to a global market. The study included an extensive analysis of stakeholder interviews, a cost-of-goods-sold analysis, and a review of manufacturing processes, as well as additional surveys, literature reviews, and supporting data analyses.

Through this research, the project identified the cost and lead time drivers for LLINs, eventually identifying several benefits if PMI developed targeted guidance on LLINs customizations. Cost savings could reach up to $7 million per year—enough to purchase an additional 3.5 million nets for families at risk of malaria. Order fulfillment lead times could be reduced by as many as five months, increasing the time countries would have to plan for the year ahead and enabling a quicker turnaround for emergencies. In addition, if all countries were using similar nets, PMI could much more efficiently and quickly shift stock between countries in emergency situations such as natural disasters, weather changes, disease outbreaks, or other unexpected shortages.

The analysis further found that LLIN variations largely came from small details, like custom artwork on the packaging and added accessories. Although the benefits of reducing the available options seemed clear, GHSC-PSM also wanted to be sure that reduced options wouldn’t have a negative impact on users at the household level. The project’s literature review found that most countries were, in fact, already requesting similar nets: for example, 98 percent of all LLINs were rectangular and 64 percent of nets were white. Many net users stated that the rectangular nets fit the most sleepers and that they were easiest to hang. While users in several countries mentioned that colored nets hid discoloration for longer periods, additional research found that net color had negligible impact on a family’s decision to use it. In one literature review considered by the project, although user preferences for shape and color did exist, these factors did not significantly influence use and recipients largely used whatever nets were available to them.